Automotive

High-performance sealing for Safety, Comfort and Sustainability.

Automotive seals are made in such a way as to be protective and elastic, approved according to the strictest specifications.

Whether they are conductive or insulating, intended for low or high temperatures, designed to be in contact with liquids or oils, it is important that they offer high chemical and mechanical resistance.

Additionally, the rise of electrification and strict emissions standards have intensified the need for advanced materials that can withstand the unique demands of modern automotive engineering.

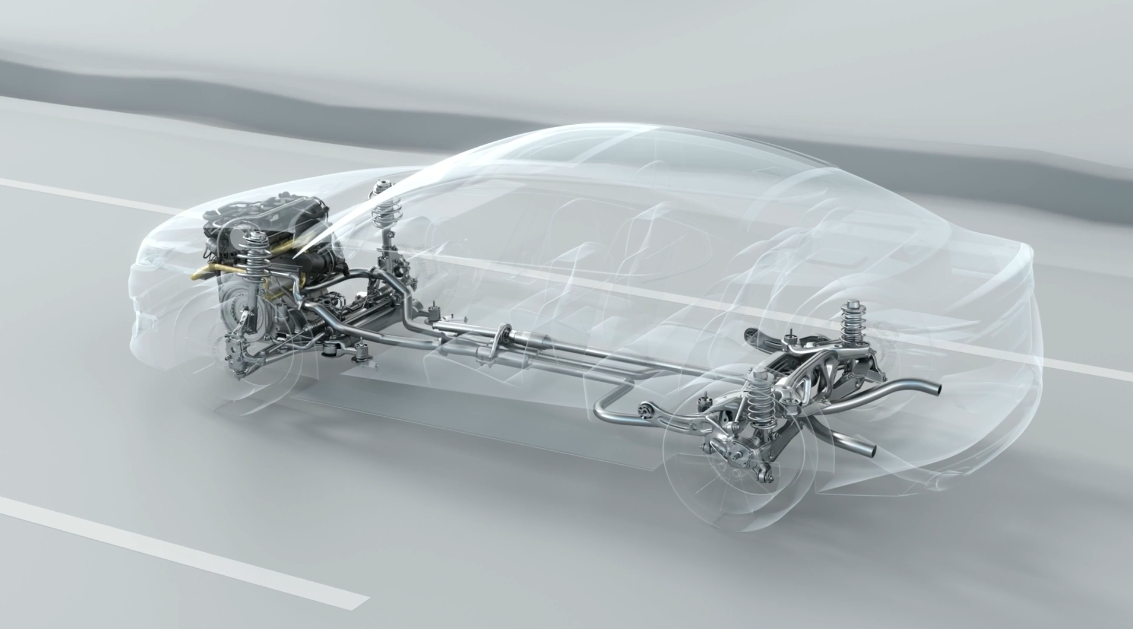

Our products are designed to endure high dynamic loads, minimize wear, reduce noise, and enhance vehicle comfort.

As a trusted partner to automotive leaders around the world, we combine high-performance materials with a deep understanding of industry-specific challenges ensuring they can deliver safer, more efficient and longer-lasting vehicles.

We manufacture sealing solutions for:

- Under the hood

- Cooling system

- Air conditioning system

- Drive unit

- Thermal management